Three months ago we opened the doors to Black Hops after a solid 12 months of planning and setup. Since our first brew on 18 June we’ve been brewing regularly on our commercial brewing equipment sourced from China.

We cover the story of our startup and the equipment at great lengths in our upcoming book, Operation Brewery. That book is about startup up, and we wanted to make sure we also had some information post-launch. One of the biggest questions we get is around how the Chinese brewing equipment we chose has been performing. Up until now, we’ve been reluctant to respond, as we wanted to hold off until the time came to give it a good honest run and push the system to its limits. We’ve now done that, so here it is, the uncensored, warts and all version of our brewing equipment experiences.

We knew from the start that by buying a system that was essentially half the price of your typical brewery, that there was likely to be some teething issues. But we also calculated that if we had to spend another 10 to 20% on fixing or upgrading problematic parts, then we would still be way ahead budget wise.

Before placing our order, we did a lot of homework on suppliers in China and spoke extensively to their other global clients to make sure we were making the most informed decision we could.

After eight months of due diligence, we finally settled on the Jinan Tiantai Brewing Equipment Company. In particular, Luke from Coda Brewing in Colorado and John from Strong Ale Works in Qingdao (an ex-pat American brewing in China) were great sources of information on Tiantai and their equipment. Many of the upgrades we made to our system were based on Luke’s 18 months experience in operating the Tiantai equipment.

First up it needs to be said that overall, we have been very happy with the performance of the system and have been particularly stoked with the quality of beer we have been able to produce.

The book goes into an exhaustive description of all equipment changes, but this post will just spell out our suggested enhancements to the components of the system knowing what we know now. Some of these are relatively trivial or only relevant to our setup, while others are more impactful.

Hot Liquor Tank

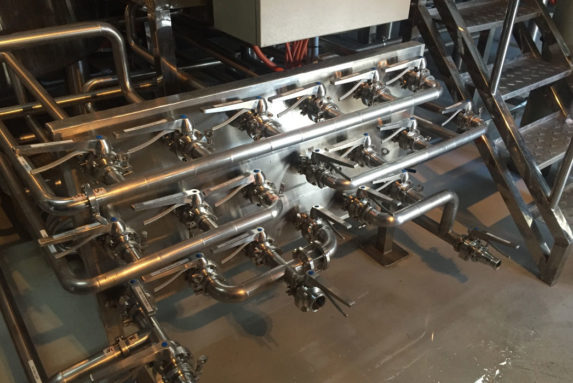

We added a fin to the bottom of the tank to prevent whirlpooling. But one thing we found is that due to the nature of steam jacket heating, the liquor stratifies and the temperature is not uniform from top to bottom. This means Govs has to connect a mobile pump to recirculate when heating to get an accurate temperature reading. So we would upgrade the brewhouse pipework to be able to recirculate the hot liquor tank without an additional pump.

Mash Tun

Remove the sightglass, it’s not necessary and just gets clogged up. Instead, we’d suggest including a measured dipstick to test the volume.

Our mash drain is not the lowest point of our brewhouse, which makes it hard to empty completely. So we would raise the brewing vessels (lauter and kettle) to ensure the drains flow freely out.

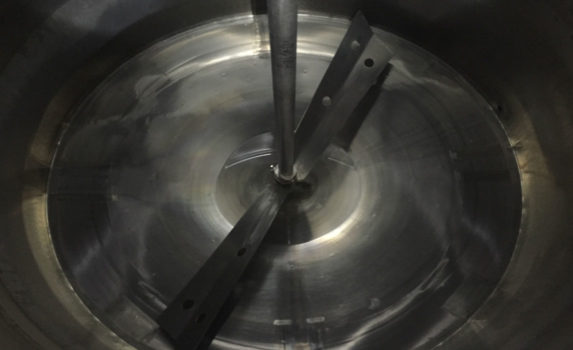

Lauter Tun

Upgrade the rake motor to something more heavy duty, to allow stuck mashes to be cleared effectively. We have been quoted about $1000 to have this done locally.

Make the false bottom panels easier to raise to improve the cleaning procedure, and have a flatter bottom with multiple draining ports to reduce the channelling of wort.

Have a diverter plate or vorlauf-arm on the recirculation inlet to reduce splashing.

Include a wort-grant to better manage runoff and vorlauf speed/efficiency.

Kettle/Whirlpool

We added a side-port outlet and changed the position of the whirlpool arm, which has proved very effective and resulted in great work clarity.

Heat-exchange

Remove the glycol inlet/outlet, it’s not necessary. We get great cooling power just using cold liquor.

Cold Liquor Tank

Include a sightglass and the ability to recirculate the tank (same as hot liquor) to reduce stratification.

Brewhouse pipework

As mentioned earlier, make sure all drains flow freely and are the lowest point of the system and make sure it is easy to CIP each pathway.

Fermenting Vessels

Increase the size of the dry-hopping port to make it quicker to get hops in.

Bright Tank

Add a separate CIP arm. Ours only has one.

Glycol system

We opted to have two glycol chillers as a bit of a redundancy to our system, but alas both pumps on the chillers failed at the same time. We lost all of our $3,000 worth of glycol, plus it cost another $7000 to replace the pumps and refill the glycol tank, and we were unable to brew for a week. Tiantai have said they will cover these costs under warranty, which is in the process of being resolved. Apart from this hiccup they have been performing well, but cooling and heating are processes many people chose to buy locally due to their importance.

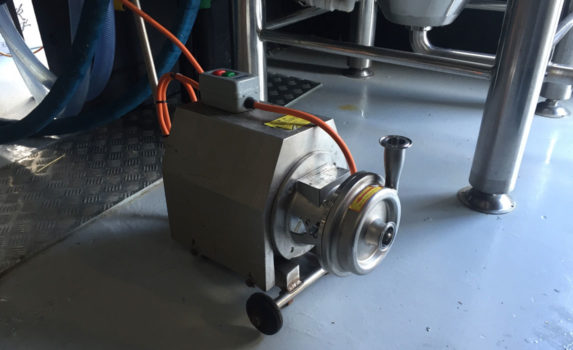

Mobile pump and grain mill

Some of you might have read that we had trouble with our mill and pump. This was a problem with the local electrician we had install them and not a problem with the equipment itself. The electrician did not have much experience working with 3-phase industrial equipment and did not install overload protection. This resulted in the motors burning out and needing to be replaced, which cost about $800 each.

The pump and mill have been solid otherwise.

Keg Cleaner

This simple piece of kit has performed extremely well. It does need to be manually operated, but having this control gives us reassurance that each cycle is being completed properly.

Yeast feeder/propagator

To be blunt, the yeast feeder we got is useless. It’s almost impossible to CIP and therefore we don’t use it at all. It could potentially double as a hop-back but we’ve yet to try that. Tiantai have since upgraded their yeast feeders to a more practical 50L keg design with 4” triclover for CIP. This is something that was overlooked during our ordering process, so lesson learnt!

Bottle filler/capper

We bought this during our visit to the factory in China and have been using it extensively for the past three weeks. It’s a manually operated four head counter-pressure filler with the ability to co2 purge. We’ve found it to be very slow – it takes about 9 – 10 minutes to fill a carton!

However it gives us the ability to sell takeaways at our onsite taproom and at retail prices we make decent margins. It wouldn’t be effective for wholesale production, but often just having some bottled beer in the market (even at cost) is positive for brand exposure. We haven’t had time to properly test shelf life, but at the moment most of our bottles are with customers within seven days of packaging.

PDL bag filter

We bought this as a cheap filtration option, but to be honest it doesn’t really do anything to remove yeast load. It’s good for capturing hop debris, but we don’t use it and could probably live without it. We use biofine clear and find that 1-2 days in the bright tank gives us exceptional clarity.

So that’s been our experience with using the Tiantai equipment, from purchasing it ten months ago through to brewing on it full time for the past three months. We hope that by sharing our insights, it will help you to optimise your chosen system, whether it be Tiantai, or any other supplier.

If you have any questions about any piece of equipment you might be looking to purchase, please post it in the Black Hops Ambassador Facebook group. Also for a rull run down of our story and the ins and outs of doing busines in China, check out our book Operation Brewery.

Cheers and happy brewing!

Govs and the Black Hops Team.