Things to watch out for when canning

When it comes to canning, there are a number of potential risk factors and quality compromisers that can mean your beer doesn’t live up to standard. The good news is, that by having some smart and sensible checks and balances in place, as well as having a switched on and diligent canning and packaging crew, we have a bit of control over these factors.

So let’s have a look at a few of these canning risk factors and how we go about minimising their potential impact.

Oxygen pick up

Oxygen and beer have a unique and interesting relationship. During the early stages of fermentation, oxygen is vital in facilitating healthy yeast growth, which the yeast consume, along with malt sugars. This occurs in what is known as the ‘aerobic respiration phase’, which encourages reproduction of more yeast cells to build up to a population capable of fermenting the entire volume of beer and also preventing any other organisms from settling. This process usually occurs within the first 24 hours of the brewing process.

Once this process is complete and the yeast have respirated all of the available oxygen they shift their metabolic pathways and commence active fermentation. This stage involves them consuming sugars and instead of reproducing, they produce ethanol alcohol and carbon dioxide – aka the buzz and the fuzz! Introducing oxygen after the yeast have commenced active fermentation will cause the malt and hops in the beer to start going stale, just like it does to most food products. It may also cause the yeast to produce some unwanted off-flavours and aroma compounds.

Here’s how we keep oxygen out of the production process:

- minimising the exposure time of the tanks by not opening them unnecessarily and creating positive pressure displacement with inert gas when doing so.

- ensuring all hoses, pumps and tanks involved in any transfers are done with strict handling processes to ensure no oxygen is picked up along the way.

This is where a Dissolved Oxygen Meter is a very important piece of kit for brewers.

However it’s during packaging, whether it’s bottles, cans or kegs, where most of the oxygen that makes it into the beer is picked up. It’s important to bear in mind that it’s almost impossible (and operationally not feasible) to remove 100% of the oxygen during the packaging process.

The way we approach this issue is to have a standard level/minimum benchmark to which we hold ourselves. For us, it is below 50ppb (or 0.00005 grams of oxygen per litre of beer).

Kegs are relatively easier to pack into as they are a completely sealed vessel, so purging and venting is more effective. However removing oxygen from an open can without a lid is a bit more difficult. It requires sufficient pressure and time to displace the gas and allow the CO2, being a heavier gas, to settle to the bottom of the can without blasting too hard. When done effectively, this creates a pocket of CO2 in the can under which the filler head can lower and fill, in theory, displacing the remaining oxygen as it fills.

Using the temperature, carbonation and fill pressure to form a thick cap of foam on top of the can prevents a cavity from forming and allowing oxygen to be trapped under the lid. The use of additional CO2 or other inert gas lines throughout the filler also helps to reduce oxygen levels around the cans. Then we need to make sure the lid is applied and seamed as quickly as possible. If that was not challenging enough, time is also crucial – this entire process needs to be completed within 3 to 5 seconds, to ensure the beer is not over exposed and also to meet production demands!

While it’s true that oxygen will not immediately stale your beer, most packaging lines have a small amount of pick-up, so it’s important to handle the beer with care after packaging to extend the freshness of your product.

Low fills

Ensuring the correct fill level of our cans is first and foremost a government regulated requirement. This ensures consumers are getting what they pay for and are correctly informed of the alcohol content on the label. It also ensures we are paying the correct amount of alcohol excise.

Equally as important though, it’s a symbol of the trustworthiness of our brand. If you start getting it wrong and get a reputation for low filling, consumers will no longer see you as a reliable brewery.

While we do our best to meet our low fill standards, we are also not in a perfect world and very occasionally an incorrectly filled can will slip past our checks and measures. When this happens, additional oxygen and accelerated staling in the can, in conjunction with insufficient head pressure, may result in the beer losing carbonation and appearing flat. Gladly this is a rarity, and we’d like to think that the quality of our beer is nearly always high and that customers are satisfied with our consistency.

At Burleigh, we use a manual, human-driven process for ensuring our low fill level targets are met. This involves one of the canning line crew literally weighing every can throughout the process, which equates to between 5,000 and 6,000 cans per shift!

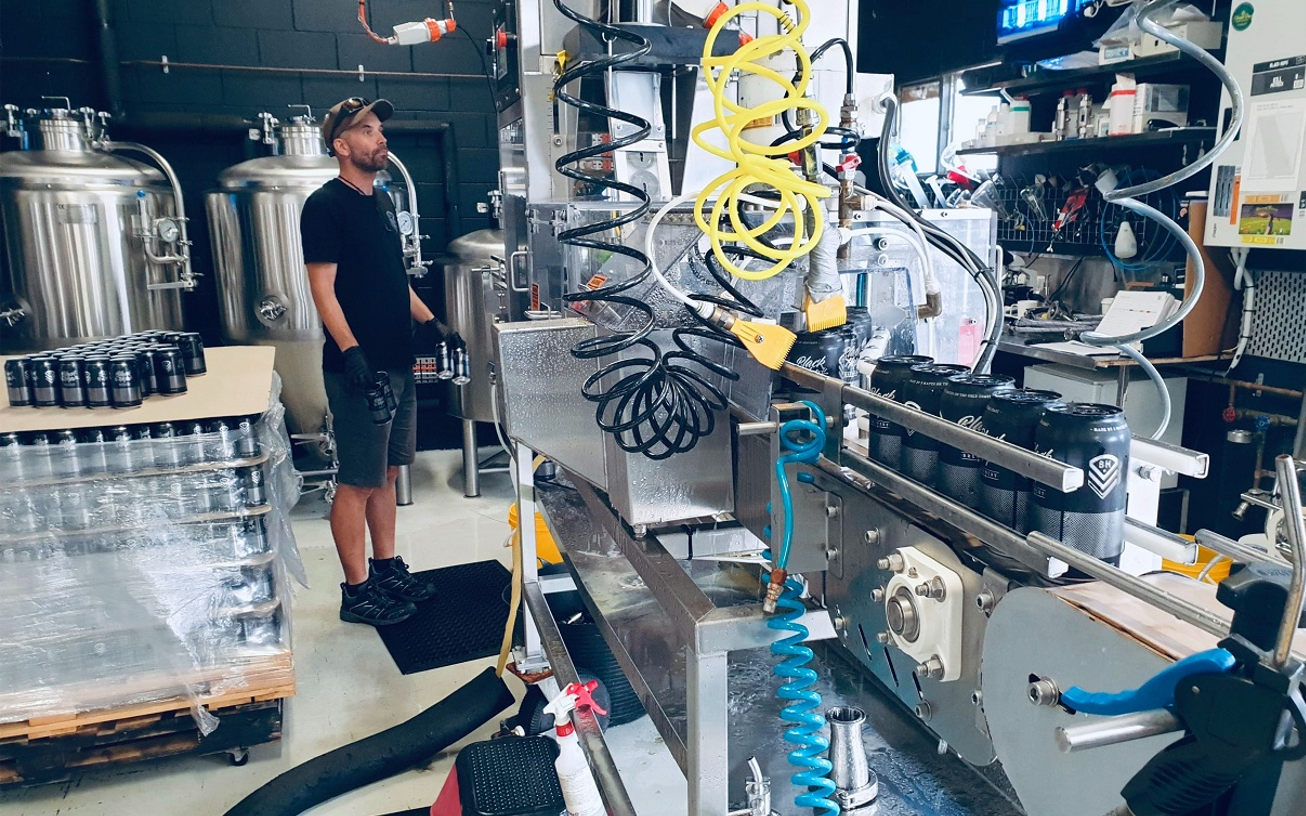

At BHII, monitoring low fills is an automated process. As the cans come along our 8-head inline canning machine (aka the ‘Beer Cannon Invasion’) they are all automatically weighed, and any low fills are spat out by the machine and quarantined by a canning line crew member. The system also keeps a statistical record of low fill numbers, and reports back to us on the results, so that we can make sure that we are meeting our ‘acceptable fill level’ targets.

Labelling issues

The way our current can design works is we have a generic can and all cans also have a thin label which is applied during the packaging run.

Making sure the labels get added to our cans in a consistently correct manner is an important part of our brand compliance and is something for which the packaging line operator is primarily responsible for.

In a craft brewery, most of the important checks are done by humans, as we are unable to implement robotic eyes that scan each can to ensure it not only has a label, but that it is correctly applied. Our packaging team do a great job in keeping labelling mistakes at a minimum. We keep on top of it though, and are always working on ways we can improve how our packaging team performs and how to prevent fatigue related errors. We also keep detailed records of our labelling losses and hold regular meetings to discuss potential improvements.

Seaming

The seaming component of canning is a precise, automated process that ensures the beer lids go onto the cans correctly by creating a hermetic (airtight) seal.

The cans go through a two stage ‘double seam action’ process (visit seam school to learn more), which takes the lip of the lid and the can itself and folds it, then it folds it again upon itself.

It’s an incredibly precise action, involving tolerances of a thousandth of a millimetre. And it’s not a case of set and forget when it comes to setting up the parameters. It all happens within half a second while everything is moving quickly, and when you’re also dealing with such precise measurements, all it takes is for one of the heads to be pushed slightly out of alignment and you’ll leak pressure and end up with compromised beer. This necessitates that we constantly monitor the equipment and adjust the settings to make sure things aren’t out of alignment.

We calibrate and test constantly, both before and continuously during a canning run (usually every 20 minutes), to make sure things remain within the specifications of achieving properly seamed, fully sealed cans. We test our seams by cutting then opening them up and measuring the height, width and length of each operation with a micrometer. Larger scale breweries use automated seam saws with microscopic cameras to inspect and measure.

At BHII we’re doing between 65-80 cans per minute, so if the cans aren’t being sealed properly (even if they look ok to the eye) we need to know about it quickly, which is why we check things so diligently throughout this process.

It’s all about creating and maintaining the perfect seal to avoid leaking pressure and gas and ending up with inferior beer.

Pre-Rinsing

Pre-rinsing involves cleaning the cans when they go from the pallet to the filler. This is done to remove any debris that might have fallen into the can between the time of unloading the pallet into the depal and prior to entering the filler. The cans should already be produced to Australian food and hygiene standards – if your cans have dirt or organisms in them before this step, you should be addressing that before you think about using them!

The cans come down a twist rinser where they’re inverted, sprayed with a cleaning agent then re-inverted back upright. When it comes to the choice of cleaning agent when rinsing the cans it’s a case of ‘each brewer to their own’ – anything from a mild sanitiser, to water, or even as hardcore as deionised air, are all valid options.

We use UV filtered water, but wait, there’s an x factor when it comes to the value of pre-rinsing, which dictates that we only do it when absolutely necessary – oxidisation! The residual water used in the pre-rinsing process will also oxidise the beer. Sterile water can be in excess of approximately 6000 parts per billion of oxygen, so it only takes a few drops of water to oxidise beer. And as we’ve already discussed earlier, this is something to avoid where possible in the canning process.

So in light of this, we don’t pre-rinse every can, we only do it when we think it’s necessary. Generally speaking our cans are kept in a clean and hygienic state when in storage, so there’s no need to pre-rinse them when this is the case. If, however, the pallets have been sitting around for weeks and may have been exposed to environmental factors such as dust, then we’ll tend to give them a pre-rinse.

It’s almost impossible to ensure the cans have no drops of water in them whatsoever after a pre-rinse, so it comes down to a trade off – 100% pre-rinsing vs the potential evils of oxidisation. I’d like to think we manage both scenarios in a practical and sensible way.

Which leads us into our next potential canning issue..

Secondary Fermentation

There are two frames of reference when it comes to secondary fermentation. The first one relates to an aspect of the brewing process, relevant to some beers.

Secondary fermentation relative to canning is a bit different though and refers to the presence of beer spoiling micro-organisms such as lactobacillus, brettanomyces and pediococcus, which will continue to ferment the beer if they are present.

These bacteria won’t make you sick, but their presence may contribute to the beer spoiling. If this is a concern, use a mild sanitiser when pre-rinsing. But keep in mind the cons of pre-rinsing, as previously discussed.

Another potential spoiler are diastaticus yeast strains, typically found in many saisons. These wild yeasts, like brettanomyces, excrete an enzyme called glucoamylase out of their cell walls that can break down dextrins and starches in beer into fermentable sugars which continue to ferment in your packaged beer, leading to over carbonation, excess alcohol and a variety of off flavours and aromas.

The big breweries pasteurise their beer to eliminate any likelihood of this, but it comes at the cost of having your beer as fresh and tasty as possible.

On the other hand we prefer a holistic outlook, using a risk management approach. We want our beer to be as fresh and tasty as possible, so we make sure we have a rigorous bacteria checking process and maintain immaculate cleanliness standards throughout the brewery and through all stages of the brewing process. We regularly test and analyse our beer for the presence of any beer-spoiling organisms. We do this ‘bacteria check’ on every batch of beer we brew. We currently outsource our bacteria tests, but we plan on setting up an in-house lab as we continue to grow, and the need to maintain our standards and ensure our cleanliness becomes even more crucial.

Reducing the risk of secondary fermentation this way means less pre-rinsing is required, which means less chance of oxidisation, win-win! Or as the saying goes, prevention is better than cure.

Chemical Contamination

One last thing to watch out for, if your canning line has a built-in cleaning system permanently connected, is chemical contamination. This can occur if, for example, someone accidentally leaves the wrong valve open during the packaging run, resulting in cleaning chemicals leaching into the beer as it is filling. Thankfully we’ve never had to deal with this, but for craft breweries with such a set up, it’s a real risk factor to be avoided at all costs. To avoid this, we:

- don’t have our CIP (cleaning in place) system connected while we are running beer.

- test the beer pH throughout the packaging run to ensure there is no contaminants (caustic or acid would detrimentally adjust the pH very quickly).

The canning/packaging line team: the glue of the process

As we discussed in the recent blog article on our canning and packaging operations, a canning/packaging line team consists of 1 operator and 3 casual workers. As well as overseeing all of the manual tasks and processes which form part of our canning and packaging production lines, they also manage the quality check processes we have in place, ensuring compliance to key standards and maintaining best practices.

This involves regular quality checks on the beer temperature and carbonation, head pressure, dissolved oxygen levels, clarity and fill levels. They also look after our can integrity tests, which involves inspecting and measuring precise lid seam tolerances and maintaining brand compliance standards around our lids, labels and date stamping. They also make sure we don’t send any damaged cans out to market. So as you can see, even if everything is running smoothly they still have their hands full!

Craft beer is particularly fragile when it comes to handling, so it’s vital that we adhere to a tight and measurable packaging process. Our team are the last port of call on the production line, and with up to 20,000 cans going out on a busy day, while we can’t physically check every single can, they play a vital role in keeping an eye on things and following our protocols to make sure our customers get an end product of consistent quality.

If you like the content we put out, please jump on our email list here, where we send out a monthly update with everything that’s happening at Black Hops. We also have the Black Hops Ambassador Facebook group, check that out here.

Cheers,

Michael McGovern – Co-founder and Brewmaster at Black Hops.