Does your beer taste like it should?

One of the greatest challenges when it comes to brewing beer at large volumes is ensuring that it maintains a consistent level of quality every time it leaves your brewery and enters the marketplace.

Your reputation as a brewer can hinge on maintaining the consistency of your product, also known as being ‘true to brand’. It’s human nature for people to remember the one bad or variable experience they had with a product or service, regardless of the 99 other times it may have met expectations.

Of course every brewer worth their hops, yeast, malt and water wants their beer to always be fresh and tasty and to smell good and feel pleasant on the palate. Nailing your recipes and adhering to strict brewing processes and quality controls will deliver you this in the majority of instances. But nothing is fool-proof and standards can either slip or be compromised. Or you may have an issue with a batch of ingredients. Or an unwanted flavour such as sulphur has contaminated your batch ..the list goes on.

This is where a Beer Sensory Program comes into play to save the day. And the good news is that it’s simple to integrate into your weekly operations with relatively little cost, space, time and effort required to set up and run it.

Note: since we published this post we’ve made a few tweaks and enhancements to how the program is run. Check out our follow-up Sensory Program story here.

What is a Beer Sensory Program and why is it important?

A Beer Sensory Program involves the regular and ongoing testing of beer samples from the point of view of it’s taste, smell and mouthfeel, to ensure it meets its ‘true to brand’ criteria before leaving the brewery. Think of it as your breweries quality control gatekeeper, ensuring that your recipes and brewing processes are being maintained 100% of the time and that your beer is free of ‘off’ flavours or smells and that it fits the criteria of being’ true to brand’.

It’s about maintaining the ongoing consistency of your brand in the marketplace. In an ever more competitive craft beer landscape, letting a compromised batch of beer escape ‘into the wild’ can do some serious damage to your reputation.

This is achieved through the ongoing training and development of a select batch of brewery employees. Their role as Sensory Panelists is to recognise any quality discrepancies in test batches of beer by using their senses of smell, taste, sight and feel.

Sensory development (via faults and flavours training and sensory panelist assessments), coupled with ongoing exposure and experience, gives the Sensory Panelist the ability to identify the presence of so-called ‘off’ flavours and smells within a test batch of beer, as well as meeting its true to brand specifications. These sensory skills can then be used to help determine that your beer is meeting it’s true to brand criteria.

Defining True To Brand

Being ‘true to brand’ means that your beer tastes, smells and (mouth)feels the way that it should. Being true to brand is not just about being absent of faults, it’s also about ensuring the correct flavours, aromas and appearance are being achieved. You can have a series of great beers that are fault-free and taste amazing but are not consistent with each other or the brand.

First though, you need something definable to measure it against. To do this, you’ll need to create True to Brand Specifications for each of your beers you are evaluating, which provide a qualitative description of exactly how the beer should present. At Black Hops we’ve established true to brand specifications for all of our Core Range beers. Here’s the one we created for Pale Ale:

- Appearance: Pale golden in colour. Medium white, persistent head. Slight haze but not murky or muddy.

- Aroma: Medium citrus reminiscent of mandarin with some low pine. Medium-low caramel malt sweetness. Low pear ester.

- Flavour: Medium-low citrus reminiscent of mandarin with some low pine. Medium-low bready, caramel malt sweetness. Lingering citrus.

- Body, Mouthfeel & Bitterness: Medium body. Medium carbonation. Medium-high, firm bitterness but not overly astringent.

This is the measuring stick we use when testing whether that next batch of Pale Ale we just brewed is in fact true to brand.

Implementing an official Beer Sensory Program For Black Hops

We’ve been operating our own in-house beer sensory testing since the brewery opened. We’ve now progressed to implementing a formalised, clearly defined process for running it.

This commenced in July, when we began rolling out our ‘real-deal’ Beer Sensory Program at our Burleigh Brewery and Taproom (HQ).

To help set ours up, we called upon the expertise of one of our most trusted beer colleagues, Steve ‘Hendo’ Henderson, who currently offers a range of brewing consultancy services and training modules. We’ve known Hendo through craft beer circles for many years, and once we’d looked closely into his newly developed Beer Sensory Program we felt comfortable that it was both a quality offering that would meet our needs, and would also integrate seamlessly into our operations.

If you’re interested in setting up your own Beer Sensory Program and you want to check out everything that Hendo has to offer, be sure to check out his Rockstar Brewer site.

Related: Podcast on Beer Quality With Hendo

There’s a definite art to writing an effective True To Brand Specification, which Hendo’s Rockstar Brewer Academy Beer Quality Essentials course covers off in detail.

Here’s the process we’ve followed in setting up ours.

Designating a Brand Owner & Sensory Co-ordinator

To run an effective Beer Sensory Program, you’ll need to first of all select a designated Brand Owner and Sensory Co-ordinator and utilise a subset of your brewery employees to act as ongoing Sensory Panelists.

Brand Owner: Govs

As BrewMaster, having myself as the Brand Owner seemed like the logical fit. As well as approving the previously mentioned True To Brand Specifications for our beers, my main role as Brand Owner is to be the point of escalation for any issues identified in true to brand testing.

At the end of the day it’s up to me to decide what to do next if a batch of beer has been identified as being potentially problematic. This may include:

- Delaying production

- Reworking or blending the beer

- Releasing it under a different name

- Sending it out anyway (if the issue is minor or inconclusive)

- Dumping the batch (worst case scenario!)

Across our entire brewing history to date, there’s only been around 3 instances where sensory ‘issues’ have been detected at a level which has required us to dispose of a batch of beer without releasing it to market.

Dumping beer is not a sign of a bad brewery, no one is exempt from mistakes or discrepancies and having the integrity to be able to destroy a batch of beer rather than sell it is indicative of a brewery that respects their processes, brand and consumers. The cost of a lost batch is almost always far less than the cost of damaging your reputation by releasing sub-par beer.

Sensory Co-ordinator: Lachie

You’ll also need to select a brewery employee to take on the role of Beer Sensory Co-ordinator. Here at Black Hops one of our brewers, Lachie is this person. He’s our go-to guy for setting up and running the regular testing sessions, co-ordinating the results and sending them off to me for review and potential actioning at the true to brand testing phase.

The Sensory Testing Panel

Your sensory panel are those brewery employees who participate in your sensory testing program. Some breweries choose a specific subset of the same employees. For us, participation is voluntary and depends on who’s available and free on the day that a test is held, which is generally once a week. Our aim over time is to train up as many of our regular staff as possible.

Some people are good at picking up certain compounds and for others it doesn’t come as easily or quickly. Some of it can be trained and some of it is more inherent. Which is why it’s important to have a good cross section of testing participants. It’s also important to maintain your testing pool numbers, or ideally add to them. Everyone will be at a different level of sensory competency, and these factors are all taken into consideration when it comes to results – not only what comes back, but who’s provided it and at what level of capability do they sit.

Some testers might be great at picking certain flavours or characteristics but may have a blind spot for others, which can be determined over time as the testers move through the testing capabilities and levels.

That way, when test results come back to me, I can reference things back to who’s provided a particular piece of feedback, which can sometimes be as important as what the feedback itself is indicating.

Getting Your Testing Environment Right

An important aspect of a sound Beer Sensory Program is making sure that your testing environment is conducive to your testers delivering worthwhile feedback.

We aim to keep distractions at a minimum, by managing or eliminating outside influences such as intrusive light, noise and odours. We do our testing before the Taproom opens and prior to lunch time, as testers’ senses won’t be as heightened after a meal. Neither will they be after consuming coffee or flavoured beverages, so we encourage our testers to drink water in the lead up and we also have it handy during testing as a ‘palate resetter’. We also try not to let the smells wafting from the brewing tanks interfere with the sensory perceptions of the testers.

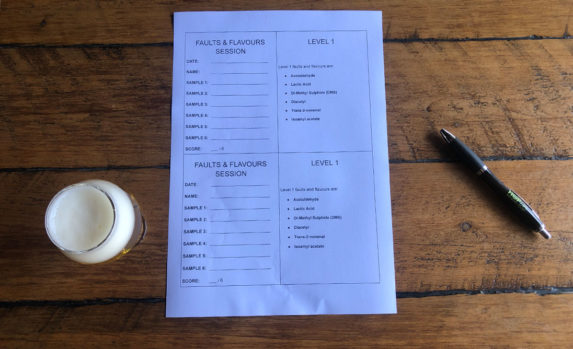

Other ways to create an ideal test environment include providing consistently correct testing materials, such as beer glasses and documentation, so that the testers become comfortable and confident in order to be competent testers who deliver accurate, worthwhile results.

Running the sensory tests

Faults and Flavours Training

Faults and Flavours Training is an ongoing weekly program where our sensory testing panel are trained to identify the different (and often subtle) aspects and attributes that make up a beers defining sensory characteristics, such as flavour, aroma and mouthfeel.

Currently we are running Level 1 Faults and Flavours Training. Panellists are presented with a range of spiked beer samples, as well as a control beer sample and will see, smell and taste each sample in order to identify one of the following irregular attributes:

- Acetaldehyde: green apple

- Lactic acid: sour

- Di-Methyl Sulphide (DMS): sweet corn/cooked cabbage

- Diacetyl: butter/butterscotch

- Trans-2-nonenal: cardboard/stale

- Isoamyl acetate: banana

Sensory testing can also be used for training employees to identify beer attributes other than flavour, such as: beer colour, clarity and head, hop and malt characteristics and ABV & carbonation levels.

Sensory Panel Assessment

Once we’ve completed all of our Faults and Flavours training, we’ll then be moving onto the Sensory Panel Assessment phase. This is where we’ll be establishing how well each of our panelists can pick the flavours and attributes they’ve previously been exposed to as part of their Faults and Flavours training. Results will be collated and panelists will be graded and rated according to their sensory abilities as part of a formalised testing and grading process.

Each panelist will have their own unique sensory skill set and grading. Some panelists may be great at identifying 5 of the off flavour attributes but may have a ‘blindspot’ for identifying one of them. Documenting this is an important aspect of any future analysis of feedback, for instance for the purposes of true to brand testing.

True To Brand Testing

Once our Blacks Hops sensory panellists have completed the faults and flavours training and assessment phases, we’ll start running formalised True To Brand tests, to determine whether a sample of beer that has just been brewed is representative of it’s true to brand specification and is fit for release.

We’ve been doing our own version of true to brand sensory testing on an informal/ad-hoc basis since we opened the brewery. So for us this is about having some specific and measurable processes in place as part of a formalised Beer Sensory Program.

Establishing our Beer Retention Library

As well as running true to brand testing on freshly brewed batches of beer, we will also be doing it with our beer at various ageing points in its lifecycle. Essentially we want to know how our beer matches up to its true to brand criteria across all stages of its lifecycle. This will help us in compiling a whole heap of useful data. For example, if we can establish the level of natural flavour deterioration of our beer at different monthly stages of its lifecycle, this will equip us with the knowledge of knowing its best shelf life.

The results of our ongoing true to brand testing are being compiled in our Beer retention Library.

Beer Quality Control Part Two: stay tuned..

An effective Beer Sensory Program is a key ingredient of maintaining quality control standards for your brewery. But it’s not the only thing we do around here. There’s plenty of other formalised testing procedures in place throughout the brewing process, from raw materials through to finished goods.

But that’s a whole other article, so stay tuned for Part two..