One of the greatest challenges when it comes to brewing beer at large volumes is ensuring that it maintains a consistent level of quality every time it leaves your brewery and enters the marketplace.

As well as our strictly controlled brewing processes and a robust quality lab set up, another way to ensure that we get this right is by running an in-house Beer Sensory Program, so that our beers meet their ‘true to brand’ criteria before leaving the brewery.

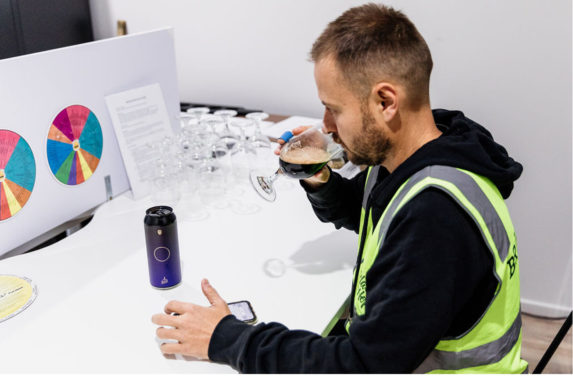

A Beer Sensory Program involves the regular and ongoing testing of beer samples from the point of view of it’s taste, smell and mouthfeel by a select batch of brewery employees. Their role as Sensory Panelists is to recognise any quality discrepancies in test batches of beer by using their senses of smell, taste, sight and feel. Sensory development (via faults and flavours training and sensory panelist assessments), coupled with ongoing exposure and experience, gives the Sensory Panelist the ability to identify these quality variables.

In 2019 we published an article on how we put together our initial Beer Sensory Program. You can read about it here. Since then we’ve taken things to the next level with our sensory testing sessions. Here’s what’s new and what else we’ve done.

More Participants and More Testing Sessions With Different Variables

We now run a group sensory panel every day, and moving forward we will look at hosting training sessions at each of our three breweries on a weekly basis.

We currently have a total of 53 staff in our testing pool, with around 25 testers doing an average of 13 different sensory panels a week. Numbers are usually capped at around 10 testers for the group sessions.

When conducting our daily panels, our goal is to get at least 10 panelist results. This gives a good spread of answers and more validity to the results, however, it can be difficult for some people to attend the sessions at the brewery during the day (whether they are sales guys offsite or busy taproom crew that don’t have the time). So another new and very unique element we have introduced to our sensory program is our ‘Sensory at Home’ initiative.

We have a fridge stocked with daily samples that can be taken home to test and we’ve put together a guide for our team to help them set up a suitable sensory environment at home and allow them to do it in their own time. This has resulted in a noticeable increase in panelist attendance, which means more data – and more data leads to better beer!

The value of incorporating a large percentage of our employees into the program is twofold. As well as building a big pool of participants to call upon, it also encourages all employees to feel part of our quality program, to empower them through training and to give them the confidence to speak up at any time when they think something is not right with our beers.

Testing For More Attributes & Variables

When we first set up our Sensory Testing Program we focussed primarily on getting our employee testing panel equipped to identify the different (and often subtle) aspects and attributes that make up a beers defining sensory characteristics, such as flavour, aroma and mouthfeel.

A primary component of this testing is around ‘faults and flavours’, where panellists are presented with a range of spiked beer samples, as well as a control beer sample and will see, smell and taste each sample in order to identify one of the following irregular attributes:

- Acetaldehyde: green apple

- Lactic acid: sour

- Di-Methyl Sulphide (DMS): sweet corn/cooked cabbage

- Diacetyl: butter/butterscotch

- Trans-2-nonenal: cardboard/stale

- Isoamyl acetate: banana

Since that time we’ve also been running weekly sensory training sessions for equipping employees to identify beer attributes other than flavour. These include:

- sensory sessions for raw ingredients where we smell hops and taste grain and adjuncts such as spices and yeast.

- sessions where we taste a range of beers from a bottle shop ‘blind’ for a particular style (eg. Pale Ale) and include our own Pale Ale, then compare the results

- sessions where we assess water from different processes of the brew house.

- assessing beer at different stages of the brewing process (eg. wort, day 4, 10, 15, Bright etc

- comparing beer at different ages. For example Pale Ale at 15, 45,90,135 and 210 days old.

- comparing warm storage vs cold storage for beers of different ages.

- using aroma standards (a set of known specific aromas, such as pine) and asking our panelists to correctly identify each known aroma. This helps ensure that all testers are on the same page when identifying aromas in beer and not accidentally reporting conflicting reports of aromas and will help bring our shared knowledge closer together as a brewery.

Incorporating The DraughtLab App

Another enhancement we’ve made to the program since it started is to utilise the App DraughtLab to run the testing sessions and analyse and report on the results.

This has been driven by our Sensory Coordinator Benedict (aka Biff), who’s our go-to guy for setting up and running the regular testing sessions, coordinating the results and sending them off for review and potential actioning. Biff works closely with our Quality Lab Manager Louise to plan the sensory panels and formulate the structure of the program, as well as with our Brew Master, Govs.

Biff had previously used the App in his own time to help build and develop his vocabulary for reviewing beers. Having seen its potential as a worthwhile support tool for our Sensory Program, he brought it to the attention of the Quality Team and Govs, who had recently completed an online course in quality systems. From there we were able to implement and integrate it into our existing Quality processes.

We started using DraughtLab as part of the weekly testing process in April this year and it has helped in lots of different ways. It is very quick to set up a new sensory test and as soon as anyone completes an assessment the data is live and can be viewed by quality and production managers.

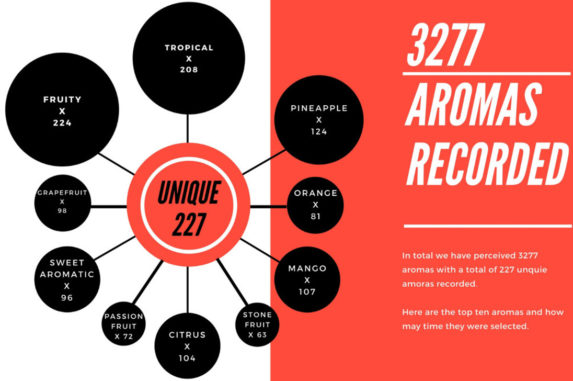

Another big impact is the way the App is set up to support flavour profiling. This occurs through a functionality known as flavour maps, which drills down to very specific flavour attributes. For example, selecting a general aroma such as ‘fruity’ gives you a new list of options (such as tropical and citrus) and from here testers can drill down to a specific aroma, such as ‘pineapple’.

Not only does this provide more useful feedback on the specifics of the beer but it is also helping to train the tasting staff to heighten their sensory perceptions by having to pick very specific, individual aromas out of a beer instead of just relying on a more generic term such as ‘tropical’.

All of this is helping to build a shared lexicon for the brewery and tasters so that we are all on the same page when tasting beers.

Using The App To Facilitate A Testing Session

We use DraughtLab to do all our sensory evaluations, off flavour training, aroma standard training, individual sensory sessions and group sensory sessions.

Biff our Sensory Coordinator is responsible for setting up and scheduling each testing session in the App. To begin he selects the brand and the type of test to take place:

- Descriptive: this is where testers are asked to describe the mouthfeel, aroma and flavours of the beer (eg. fruity / stone fruit).

- Hedonic: this is a simple test that asks if the tester likes the beer.

- True To Brand (TTB): tasks the tester to evaluate the beer against our True to Brand guidelines for the beer.

Details such as batch numbers, brew dates and tags are added, based on the type of reports to be generated at the end. These details can be hidden from test participants if needed, for example when testing retention stock and we don’t want the taster to predetermine that the beer is bad because they already know the age of the beer or batch.

From there, sensory participants will be advised of the testing start time, with the beer(s) to be assessed ready in our controlled sensory room. We discussed the importance of having an appropriate test environment in our previous Beer Sensory Program article.

Once present for the test, participants will then access the App, and evaluate/score the beer or log their findings as required.

In the group setting we try to keep quiet until everyone has evaluated the beer(s), prior to opening up a discussion on the results. Often an experienced brewer will be on-hand to give some insights and Biff will also walk through a summary of results to highlight what the majority of people were experiencing on a sensory level. As well, participants might also be asked to predict factors such as the age of the beer(s) and if it was cold stored or warm stored. Perceptions and results can sometimes be surprising!

Results Analysis And Reporting

Another great feature of DraughtLab is its ability to generate meaningful data on the outcome of sensory sessions, such as:

- Faults and flavours training reports

- Attendance reports

- Product release charts

All of these can be viewed via parameters such as date, brand, batch, tag and user. Other value-add features include a description builder and an issues tracker.

The data is easily exportable and can be combined with brewhouse data to track brands and batches, the flavour profiles of particular beers and data on tasting sessions such as:

- top aromas

- brew date vs hedonic score

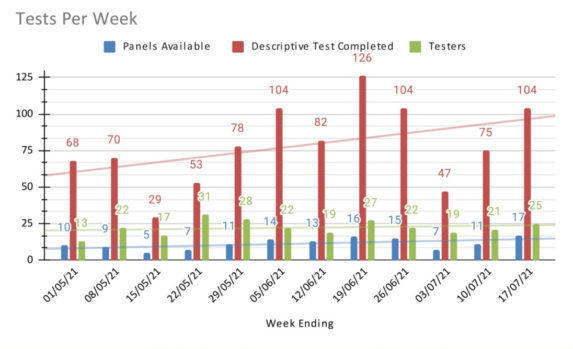

- the types of sessions held per week (test panels vs individual assessments taken vs unique tasters).

Here is a snapshot of some of our most recent data and results:

Biff also presents a summary of the results each week to our Brew Master Govs and they discuss how each panelist is performing. They look at what flavours/aromas are being detected, the percentage and the threshold levels (how much of each compound was in the test sample). This then provides direction on where best to move with the training sessions so we can focus on areas with most value.

Sensory Panel Assessment

We are currently working on grading our tasters, with the view to completing a comprehensive sensory panel assessment. This is where we’ll be establishing how well each of our panelists can pick the flavours and attributes they’ve previously been exposed to as part of their sensory training. Results will be collated and panelists will be graded and rated according to their sensory abilities as part of a formalised testing and grading process.

Each panelist will have their own unique sensory skill set and grading.

As well as adding a level of gamification to the process to make it fun for participants, the aim of sensory panel assessment is to have different levels of panelists whom we can assign different levels of responsibility to. We can also see who is reliable at detecting each flavour compound and direct different tests to the most qualified people. For example once a panelist reaches Level 2, we can assign them to do release tests and once they’re at Level 3 they are able to perform even more highly honed assessments, such as retests.

As with everything to do with human senses, each individual is very different and some people have genetic blindness to certain flavours, while others can detect some at the lowest threshold levels and being able to determine this is very valuable. Most people will generally improve over time with regular exposure to each compound and that is why it is important to keep our training up.

As always, if you have any feedback or questions feel free to ask in the comments below.