Here at Black Hops we’re very serious about making sure our beer tastes fresh, maintains a consistent level of quality and is free of contaminants every time it leaves the brewery and hits the marketplace.

Nailing your recipes and adhering to strict brewing processes and quality controls will deliver you this in the majority of instances. But having a robust Beer Quality Program is the ‘next level’ barometer for making sure you get it right.

In this blog post, we’ll expand on a recent blog post about our Beer Sensory Program to let you know about the development of our new Quality Lab. This is where we get scientific when it comes to making sure our beer adheres to standard every time.

Our Beer Quality Program To Date

As a craft brewery we don’t go down the road of pasteurizing our beer (like the big breweries) but prefer to use a holistic outlook, using a risk management approach. We want our beer to taste as fresh as possible. So we make sure we have rigorous testing processes and maintain immaculate cleaning and sanitation standards throughout the brewery and through all stages of the brewing process.

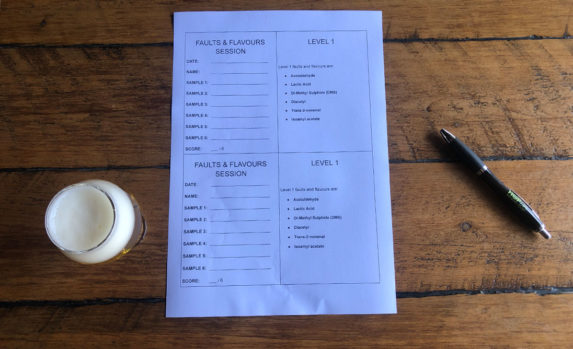

To date we’ve been approaching our beer quality responsibilities through:

- Good manufacturing practices

- Food safety

- Process controls

- Standards

- Analysis

- Continuous improvement & preventative maintenance

Our new lab, together with our developing beer sensory program/panel, form part of our analysis resources that give us information on how our practices, processes and controls are performing.

Our Beer Sensory Program/Panel approaches our beer quality from a qualitative perspective. It involves the regular and ongoing testing of beer samples from the point of view of taste, smell and mouthfeel, to ensure it meets its ‘true to brand’ criteria before leaving the brewery. You can read in-depth about our Beer Sensory Program here.

Since day one of opening our breweries we’ve been diligent in keeping strong quality control procedures through every phase of the brewing and canning process. We have processes in place to prevent issues such as oxygen pick up, chemical contamination and low fills. We also follow sensible hygiene procedures.

The canning crew play an important role in maintaining our quality control standards, ensuring compliance to key standards and maintaining best practices. This involves regular quality checks on the beer temperature and carbonation, head pressure, dissolved oxygen levels, clarity and fill levels. They also look after our can integrity tests, which involves inspecting and measuring precise lid seam tolerances and maintaining brand compliance standards around our lids, labels and date stamping.

Related: Things to Watch Out For When Canning

At a quantitative level we’ve always had a random sample of our beers submitted for chemical and microbiological analysis following every canning and packaging run. As we now have the tools to do our own in house testing, we send off random samples once a month as a Quality Assurance test to validate our testing processes.

We test and analyse our beers for the presence of any beer-spoiling organisms. We do this ‘bacteria check’ on every batch of beer we brew. We test for beer spoilage organisms at several critical points throughout the brewing, fermenting and packaging process. Quality testing is not just all about testing for problems either, most of our quality analysis is ensuring that we are achieving all the desired outcomes throughout the process (such as gravity, pH, temperature, yeast health and fermentation characteristics).

Vintessential Laboratories have helped us with this, to identify any potential issues such as secondary fermentation.

Now that our Quality Lab is fully operational we’ll be able to do all of this testing ourselves. But there will be a transitional period where we’ll continue to use Vintessential Laboratories to verify our test results, until such time that we’re comfortable in the accuracy of our findings and we have our own processes bedded down.

We’ll go into more detail on the ins and outs of this analysis further on, when we talk about our own lab set-up.

Building Our Own Quality Lab

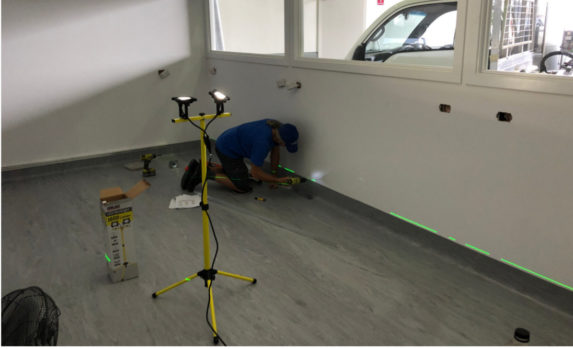

We’ve just completed the build and set up phase of our own in-house Quality Lab, where all of our beer will be scientifically analysed through every stage of the production process to make sure it makes grade every time.

The Quality Lab is set up at our large scale production brewery, BHII, at Biggera Waters on the northern end of the Gold Coast.

Here’s a few pictures of the build phase and final fit-out..

Bringing In A Quality Manager

If you’re going to be serious about having a Beer Quality program in your brewery, then you’ll need a designated person to run it. So recently we hired a Quality Manager, Louise Keane. Reporting directly to the Brewmaster (me), Louise is in charge of managing and executing our quality control systems, performing regular tests, analysing data and ensuring the brewery is safe and clean. She has a strong background in laboratory work and testing and has fitted in seamlessly with our operational side of things.

A Rundown Of Our Quality Lab Testing Regime

So what, specifically, do we test for when scientifically analysing our beer samples to ensure they are compliant with our recipes and standards? Broadly speaking, the testing process can be broken down into two specific areas:

- Chemical testing

- Microbiological testing

Let’s delve a bit further into each of these..

Chemical Testing

Chemical testing is essentially measuring levels of various substances that are directly responsible for flavour and stability to ensure they are within a certain specification and fit for consumption. Each of our beers will have a different set of specifications depending on the type of beer and what we want it to taste/look like.

The main chemical tests we carry out are:

ABV – Alcohol by Volume. This is the alcohol percentage of the beer. It is extremely important that the percentage of alcohol in the beer matches what is printed on the front of the can. The ABV is measured via an enzymatic reaction on a piece of equipment called the BeerLab, which is discussed further below.

IBU’s – International Bitterness Units. This is a measure of the concentration of isomerised-alpha-acids in the beer, which are responsible for the bitter taste. Depending on the character of the beer the bitterness may be higher or lower. This test is also performed on our BeerLab by extracting the iso-alpha-acids from the beer and quantitatively measuring using a particular wavelength of light (270nm).

Wort and Beer Colour. We do this via the EBC (European Brewery Convention) method. It enables us to quantitatively measure colour using the BeerLab at a particular wavelength of light (430nm). The sample must be filtered before measuring and can be performed in under a minute.

VDK – Vicinal Diketones. These are products formed during fermentation and typically produce flavours of butterscotch or caramel and when present have a huge impact on reducing hop character. Towards the end of fermentation the yeast naturally ‘mop up’ any remaining VDK in the beer as an energy source. Excessive VDK levels can be a sign of improper fermentation or possible infection from bacteria or wild yeast, therefore most brewer’s will consider the presence of VDK to be a defect of the beer. Once our beer has finished fermenting, we take a sample from the fermentation tank and measure for the presence of VDK using our BeerLab.

pH. This is the level of acidity in our beer which contributes to the tartness or sharpness of the beer. We test the pH of our beer throughout the brewing process, twice a day during fermentation, before packaging and after packaging.

Gravity. This is the relative density of the liquid and an indication of its sugar content. During alcohol fermentation, yeast converts sugars into carbon dioxide and alcohol. The decline in the sugar content and the presence of ethanol (which is appreciably less dense than water) drop the density of the wort/beer. The final gravity allows us to calculate Alcohol content and also the body of the beer or how “dry” it will taste.

Equipment Used

BeerLab

Supplier: CDR FoodLab

Model: SLB222

The BeerLab is a spectrophotometer which uses various wavelengths of light to detect and measure substances within our beers. ABV, IBU, colour and VDK tests are all performed using the BeerLab and each test comes with their own individual test kits. These kits include various chemicals and reagents which need to be measured and mixed with the beer in very precise quantities (we’re talking microlitres) in order to achieve the results. So a steady hand and great attention to detail are essential!

pH Meters

Supplier: Hanna Instruments

Model: Edge pH Meter HI2002-03

Supplier: Hanna Instruments

Model: Portable Beer pH Meter HI98167

This is perhaps one of our easiest and quickest tests, used to measure the acidity level of our beers. We simply lower the probe into our sample of beer and the pH level appears on the screen. The pH meter requires weekly cleaning and daily calibration in order to keep it working effectively and allows us to obtain accurate results.

Things to consider when buying a pH meter include:

- what accuracy you need

- at least 2 point calibration

- electrode is suitable for the liquid

- auto-temp compensation

pH is not a true indication of how ‘sour’ you beer is when it comes to wild ales. Total or Titratable acidity needs to be considered.

Microbiological Testing

Bacteria and contamination from various microorganisms can spoil beer and also cause issues such as re-fermentation within a can or keg.

The main microorganisms we test for here are Lactobacillus, Pediococcus and Brettanomyces. These can cause many off-flavours in the beer, therefore it is one of our most important tests. We carry out this test two days after each brew day (this gives any bacteria enough time to multiply and become detectable) and after every packaging run.

We also test our heat exchanger, fermenters and bright tanks before running wort/beer through them with an ATP meter. We then conduct a BeerPAL test on the beer within 48 hours of filling a tank.

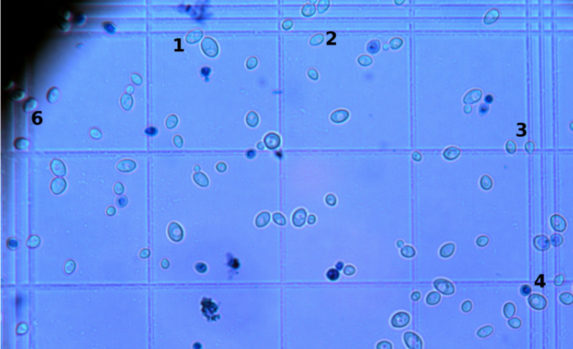

We also carry out yeast analysis testing as part of our microbiological testing regime. Our yeast testing is arguably more important than our bacteria testing. Having a healthy yeast culture is critical to producing consistent quality beer. We test our yeast before every pitch for cell-count density and also the viability and vitality of the cells, not just the absence of bacteria. As we reuse our yeast for up to 10 generations, it is critical for us to ensure our yeast is healthy and performing.

Equipment Used

Invisible Sentinel SimpliAmp Thermal Cycler

Supplier: AMSL (For Thermo Fisher Scientific)

This equipment allows us to detect a number of different organisms throughout the entire beer production process. This equipment also comes with different test kits depending on the type of bacteria we are testing for, similar to the BeerLab. Samples are placed inside the machine, where they are subjected to a range of different temperatures over a two and a half hour cycle. This amplifies the DNA of any bacteria which may be present. At the end we simply transfer the sample to a small cassette shown below, and with the addition of a few more reagents it will give us either a positive or negative result. One red line in the sample window indicates a negative result, two lines indicates positive. The intensity of a second red line also gives us a quantitative indication as to how heavily infected a sample may be.

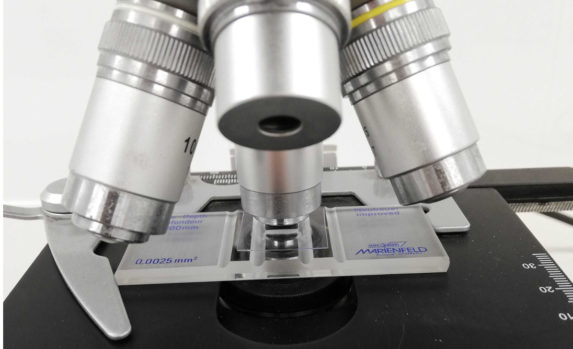

Microscope

Supplier: Amscope

Model: 1765092

When doing yeast counts we take a sample of our yeast, dilute it if necessary and place a few drops onto a hemocytometer. This is a small glass plate which contains a grid. We then look at this grid under the microscope and it enables us to easily count the yeast cells. The grid is made up of 25 squares, we count the total number of yeast cells present in five of the squares which gives us a good idea of how many yeast cells are present overall.

Another aspect of yeast counting is viability. We want to know what proportion of our yeast cells are actually active and able to convert sugar to alcohol. We add a dye to our yeast sample called methylene violet, this dye stains all the cells which are dead or no longer viable as there cell walls are unable to stop the dye entering the cell.

Other Lab Equipment

There’s a whole bunch of other support equipment that we also utilize in the lab:

Hydrometer: Used to measure the gravity or density of our beers. The more dense the liquid, the more sugars available.

Density Meter: A hand-held digital device which measures gravity.

Centrifuges: Separates a mixture by spinning at very high speeds. Mostly used to prepare samples for analysis.

Ultrasonic bath: Used to remove gas from a sample. This is required for all the BeerLab tests as the carbonation can affect the result.

ATP Meter: This is a hand-held device used to check for any bacterial contaminants around the brewery. The MVP ICON system detects food and microbiological residues by measuring Adenosine triphosphate (ATP) using luciferase bioluminescence. ATP is found in most food residues and all bacteria, yeast and mold cells. The area to be tested is swabbed, the swab is placed inside the device and gives us a positive or negative result.

Orbital Shaker: This is used to continuously mix samples.

Equipment maintenance and Calibration & Keeping Good Lab Practices

We also have a defined set of guidelines in place around the regular maintenance and/or calibration of the equipment. This is to make sure that all our equipment is in proper working order and is giving valid and accurate data.

Keeping the lab clean and well maintained is also a priority. A lot of it is basic common sense, but laying down clear guidelines around the maintenance of sound hygiene practices will ensure our lab testing results are not compromised by environmental contaminants.

We hope you enjoyed the post, if you would like to ask us any questions about our Beer Quality Program, feel free to jump into our free Facebook Ambassadors Group.